-

Things my daughter said…

Things my daughter said about objects, interiors, ornament and crime

I was asked by Jr-Work-Shop to do something related to kids. Not having ever worked with, by or for children I asked my daughter for some advice, she then became my muse. Her thoughts about furniture, objects and interiors are both grand and unrestricted. The ideas she has are also constantly changing, often inconsistent and based on seemingly random impulses. This project has been guided by our conversations. It is a tribute to the creative and un-ruined mind of this young person. The objects created are not necessarily children’s furniture but furniture from a child’s mental world.

During this project me and my daughter have had several talks about objects, design and interiors. After a while she directed our discussions into also including ornament and crime. Below is a transcription of one of her expositions:

What should furniture be and look like?

“It should be square, like dark blue and pink stripes, and in the middle there will be a green heart for all three, because we are three. Well yes, it’s for all three: daddy, you and me. Triangular, so there’s only places for us – that’s good, no? And then you can fix it into a four-table. Then the chair… pink and white. And on it there will be umm… a green, I mean a blue glitter… purple glitter… like heart. It will also be a little fluffy, with a pillow on it.

And a strange chair which is high – right up to the table – plus it could be a little higher, so that daddy, you, then it will look like, how will it look again? I mean the table which is triangular. What does triangles look like? Oh yes, like that… Then daddy will sit there and I will sit there… or you can sit where you want.

It, that is for all three. Then probably daddy’s… yours must hold the wight of your bum. Mm, so you can borrow one of mine. And mummy, your stool can be green with black glitter on it that sparkles, that it is made of wood. And me and mummy will paint it. I will have a chair. Umm… white, white and purple, with a purple heart that sparkles green.”Listen to the monoluge here: https://vimeo.com/202720833

Other comments of importance

About the glitter ornaments she put on every door handle and knob in our apartment:

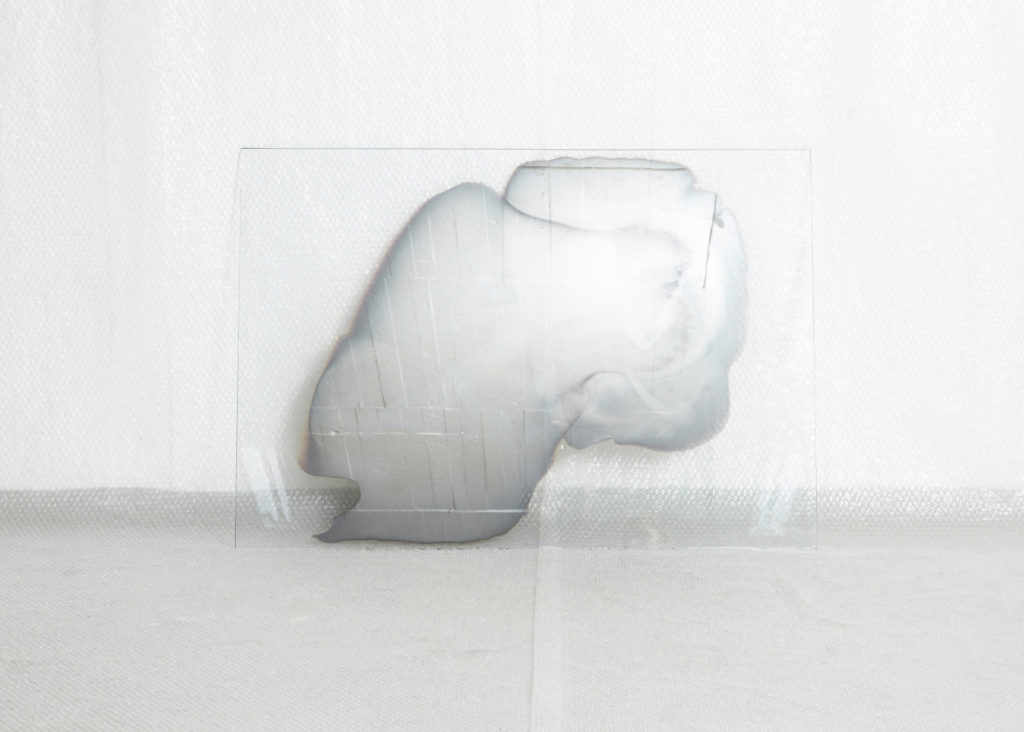

“Look how nice it is! Before, not so nice, boring. Now, beautiful!”About the drawing of her hand she gave me:

“It’s made from my hand. You can have my hand.“About the drawing on a post-it note she put on the freezer about interior related crimes:

“You’re not allowed to play ball in here.“Represented at Jr-Work-Shop during Stockholm Design Week 2017:

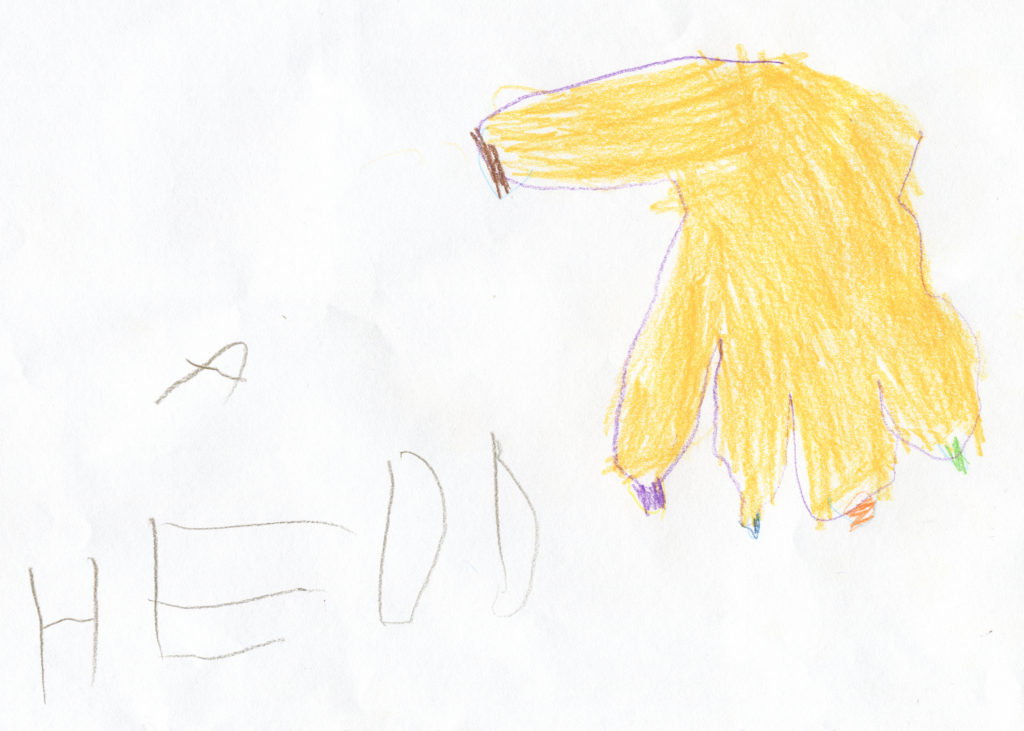

Stools in two different heights

Metallic coated steel and uncoated aluminumA transformable table for three or four

Metallic coated steelMy daughters hands

Painted MDFA prohibition sign

Painted MDFGlitter

Plant based plastic -

“It’s made from my hand. You can have my hand.“

“It’s made from my hand. You can have my hand.“ "You are not allowed to play ball in here"

"You are not allowed to play ball in here"

Category Archives: Home

-

Macro Composite

Is it possible to obtain unique results within industrial production? Jenny Nordberg has examined the issue in the Swedish foundry industry for the past year by working with three founders parallel. The result sought for has been a large scale macro-composite made of several assembled cast metals. During the process, there has been an interesting turn of events – each of the three foundries have had different theories, all of which contradict each other. The project is ongoing and has more to come.

-

Composite table

Composite table

-

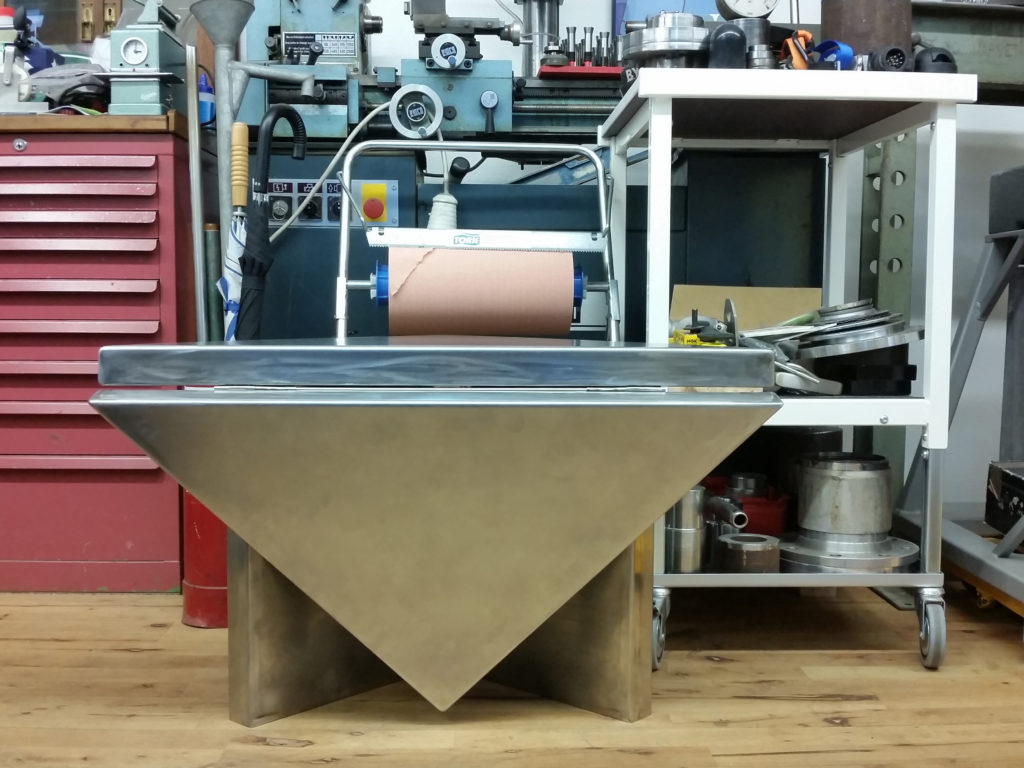

16.11.18 Tin Plinth at Etage Projects

For The Plinth Project exhibition (18/11-16-21/1-17) at Etage Projects Jenny Nordberg created the Tin Plinth with the cubical geometry of the classical gallery plinth in mind. The material in the plinth however – tin, is maybe less classical. Often working with the tension between the hand made and the machine made Nordberg wanted to explore the production of a sheet material that could be used to create a plinth. To do this she used the limitations of a studio environment as her framework, and developed a method to make sheet metal by casting tin in large molds. The outcome is an uneven and rough, almost brutal expression. The plinth and a small table are the first objects within a coming series of several industrial processes adapted for studio production.

Press images. -

-

16.02.01 Örnsbergsauktionen 2016

The Mirror Cabinet (aluminium profiles, glass and silver) will be exhibited and a part of the Örnsbergsauktionen this year during Stockholm Design Week.

Exhibition at Kägelbanan 7-12 February, auction at 19.00 PM Friday the 12th. -

-

3 to 5 Minutes

– Rapid handmade furniture

Is it possible to make unique handmade furniture really fast? Is speed the contradiction to skills? Can lack of time lead to new methods? Is there an aesthetics of the shortcut? Is speed bad?

This project is a continuation of the recent “3 to 5 Seconds – Rapid handmade production” where Jenny Nordberg explored speed in her search for ways to combine different properties of the mass produced and the handmade. This work is like many other of Nordberg’s projects a part of a larger and ongoing work about how we produce and consume today, how we’ve done historically and how it might could be different onwards.

If the first project was about examining speed in a handmade and craft oriented context, this second project is just as much about using speed as a method to achieve new expressions and procedures. The design, materials and details are all the result of the lack of time. For example – the coating does not cover the whole surface, details are few and imperfect, assembly screws are visible and the design is restrained.

“3 to 5 minutes – Rapid handmade furniture” explores the making of furniture by hand under time pressure often to found in mass production. Each piece of furniture must be made within the timespan of tree to five minutes. All production steps are clocked and added together as the designer turns herself into an artisanal assembly line. Materials and components are to be found in regular hardware stores as well as the pre-cutting of the board material. The project includes two easy chairs with additional pillows, a small trolley and a dining table with four chairs, all together made in less than an hour.

An easy chairs with additional pillow an the small trolley together with objects from 3 to 5 Seconds – Rapid handmade production project will be shown at the Stockholm Furniture & Light fair 3-8 February. The whole project including a production setting complemented by a shop will be exhibited in a solo exhibition at Vandalorum 28/2 – 6/4 2015.

Thanks to Kvadrat textiles.

-

Stencils for drilling and cutting.

Stencils for drilling and cutting. Making clay stamps for printing on fabric.

Making clay stamps for printing on fabric.

Clay moulds for handles.

Clay moulds for handles.

-

Mirrors

While working with the project “ 3 to 5 Seconds – Rapid handmade production” in 2014 Jenny Nordberg researched ancient mirror making. The process and outcome was captivating and Nordberg has since then worked with this old method of making mirrors. The process used has it’s origin in the 19th century and is resulting in a thin layer of silver (Ag) on the glass surface. Not covering the whole surface of the glass, each mirror becomes different due to uncontrollable liquids within the process of making.

-

-

15.01.30 Örnsbergsauktionen

Two of my large mirrors are in the fourth edition of Örnsbergsauktionen (the Örnsbergs Auction). Catalogue and pre-bidding. Viewing at Galleri BON 1-6 January. Auction at Friday the 6th 18:00.

-

-

14.10.25 3 to 5 seconds performance at Skissernas museum

Earlier today I did a 3 to 5 Seconds performance at the 80-year anniversary of Skissernas Museum in Lund. Picture by Andreas Kurtsson.

-

-

3 to 5 Seconds

– Rapid handmade production

WATCH THE PRODUCTION VIDEO PART II

3 to 5 Seconds is like many other of Jenny Nordberg’s projects part of a larger and ongoing work about how we produce and consume today, how we’ve done historically and how we could do it in the future. In the project 3 to 5 Seconds she examines how different properties from the handmade and mass produced can be combined. 3 to 5 seconds is about bringing together contradictions and hard to achieve qualities. The project combines the uniqueness of the handmade and the speed of the mass produced. Is it possible to make one of a kind handmade items really fast?

The various production methods in the 3 to 5 Seconds project all have in common that every moment should be made within three to five seconds. The project was begun in the summer of 2014 and is continuously ongoing. More objects and processes will be added in onwards. Read more about the three initial production methods below.

Double casting stone (2016)

Clock, jesmonite and lava stoneAxhammer bending (2016)

Pot stand, anodised aluminiumPunch and roll (2016)

Lamp, paper and electrical fittingExplosion graphics (2015)

Walk around the city of Malmö the day after New Years Eve and you will find the ground covered in the remains of fireworks. Jenny Nordberg uses fireworks attached with tape to a thick paper to create unique prints. Different types of fireworks create different looks and colours.Hook from thumb (2015)

By quickly pressing down the thump into wet clay and then pouring melted tin into it a hook is shaped. Every hook is different but holds the same fingerprint.Hand force (2014)

Clay – a classic and slow material with time a consuming process from material to finished object. The clay used in this project is a quick drying ceramic clay that does not require burning, so called study clay. The shape of the candle holder is determined by the hand, force and direction, the entry point of the candle and the original shape of the two lumps of clay.Pour out a puddle (2014)

In the traditional process of making a mirror, Jenny Nordberg eliminated all unnecessary moments and demands for perfection and total coverage. The steps left to achieve a mirror are then left to mixing three liquids, pouring the mixture onto a piece of glass and wait for five minutes. The result is a multi dimensional mirror effect of silver in indefinite puddle shape.Double staining (2014)

The goal of the double staining method is to produce both patterns and several colours in as short time as possible. The effect of dipping a folded piece of cloth in two different dyes and then hang it to dry gives both stripes, a tie dye like pattern effect and three colours with various wash effects.Cut and bend (2014)

By altering diagonal and strait cuts followed by a single bending movement the book ends are shaped. The material is aluminium, all ready precut stripes from the local hardware store, with different textures and coatings.Items from the 3 to 5 Seconds project can be bought at Center of Commerce.

3 to 5 seconds är som många andra av Jenny Nordbergs projekt en del av det större och fortlöpande arbete som handlar om hur vi producerar och konsumerar idag, hur vi gjort historiskt och hur vi skulle kunna göra framöver. I projektet 3 to 5 seconds undersöker hon hur olika egenskaper från det handgjorda och det massproducerade kan kombineras. 3 to 5 seconds handlar om att föra ihop motsägelser och svåruppnådda egenskaper. Projektet kombinerar det unika i det handgjorda och det snabba i det massproducerade. Går det att göra unika handgjorda objekt skitfort?

Gemensamt för de olika produktionsmetoderna i projektet 3 to 5 seconds är att varje moment ska ligga på en produktionstid mellan tre till fem sekunder. Projektet tog sin början under sommaren 2014 kommer att pågå framöver. Fler objekt och processer kommer att tillkomma framöver. Initialt har tre produktionsmetoder skapats, läs mer om varje nedan.

Handkraft

Lera, ett klassiskt och långsamt material med tidskrävande process från material till färdigt objekt. Leran använd i detta projekt är en snabbtorkande keramisk lera som inte kräver bränning, så kallad studielera. Ljusstakens form bestäms av handen, kraften och riktningen, ljusets isättningspunkt samt de båda lerklumparnas ursprungsform.Hälla ut en pöl

I den traditionella processen att göra en spegel har Jenny Nordberg eliminerat alla umbärliga moment samt krav på perfektion och totalt täckningsområde. Kvar för att få en spegel är då kvar att blanda tre vätskor, hälla ut blandningen på en glasskiva och vänta i fem minuter. Resultatet är en flerdimensionell spegeleffekt av silver i obestämbar pölform.Dubbelinfärgning

Målet med dubbelinfärgningsmetoden är att på textil framställa både mönster och flera färger på kortats möjliga tid. Effekten av att doppa ett vikt tygstycke i två olika färgbad och sedan hänga upp det på tork ger både ränder, en batikliknande mönstereffekt samt tre kulörer med diverse laverande effekter sinsemellan.Klipp och bock (2014)

Materialet är färdigklippta aluminiumbitarna med olika stuktur och ytinfärgningar som kommer från den lokala byggvaruhandeln. Bokstöden får sin form genom att diagonala och raka klipp alterneras och sedan efterföljs av en bockning.Explosionsgrafik (2015)

Gå runt i Malmö dagen efter nyårsafton och marken är täckt av resterna från fyrverkerier och smällare. Jenny Nordberg använder smällare fästa med tejp på entt tjockt papper för att skapa unika tryck. Olika typer av smällare och fyrverkerier genererar olika utseenden och färger.Krok av tumme (2015)

Genom att snabbt trycka ner tummen i våt lera och sedan hälla smält tenn i formas en krok. Varje krok är unik men har samma fingeravtryck.Objekt från 3 to 5 Seconds-projektet kan köpas på Center of Commerce.

-

Double casted lava stone clocks

Double casted lava stone clocks Axhammer bended trivet

Axhammer bended trivet Punched lamps

Punched lamps

Performance at Skissernas Museum.

Performance at Skissernas Museum. Hand force candle holders

Hand force candle holders  Double staining fabric

Double staining fabric Pour out a puddle mirrors

Pour out a puddle mirrors Cut and bend book ends

Cut and bend book ends Explosion graphics poster

Explosion graphics poster Hook from thumb

Hook from thumb

Performance at Krets Gallery

Performance at Krets Gallery